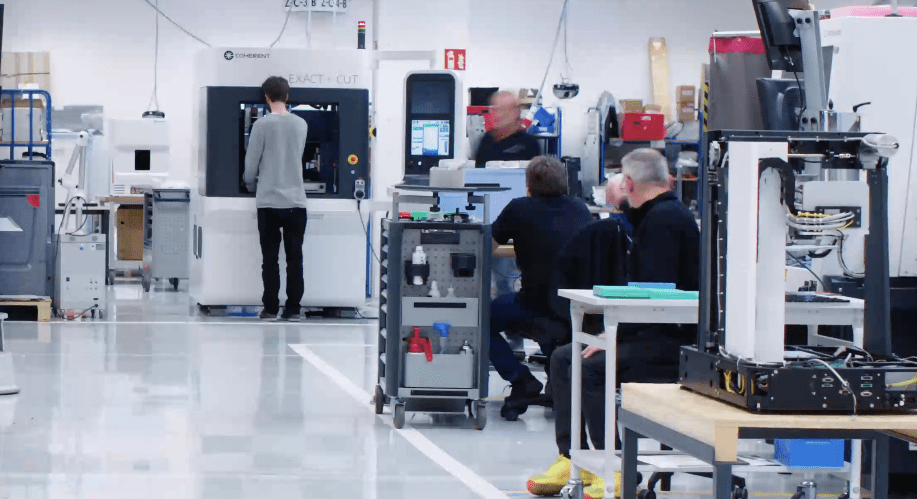

Founded in 1966, Coherent is one of the world’s leading providers of lasers and laser-based technology for industrial, commercial, and scientific customers. With headquarters in Saxonburg, Pennsylvania and offices spanning the globe, Coherent offers a unique and distinct product portfolio and services for scientific research, life sciences, microelectronics, and materials processing.

For the medical device industry Coherent supplies a comprehensive product offer based on an unmatched breadth of laser technologies. Our systems incorporate traditional lasers, as well as the latest fiber and ultrashort pulse (USP) laser technologies. These systems support manual through fully automated operation, for manufacturing single prototypes up to high-volume production. They are used by leading device manufacturers as well as small specialty sub-contractors. The main tasks that these systems enable are cutting/drilling, welding, and marking/surface texturing.

Coherent supports a wide range of laser cutting applications, including cutting of stents & scaffolds, heart valves, surgical instruments, hypotubes & guide wires, as well as thrombectomy devices. Many of these applications use our StarCut Tube systems. These are 3/4-axes CNC fully-automated laser cutting solutions with an ability to cut simple and complex geometries at a wide range of angles. The combination of a fixed beam with superior tube motion control delivers high-accuracy cutting, superior repeatability, high surface quality, plus minimized process time. StarCut Tube is available with either a fiber laser or a femtosecond laser, enabling cold cutting of virtually any material.

Coherent offers a portfolio of laser welding systems optimized for different volumes and levels of automation, with a choice of laser systems to support welding of both polymers and metals, e.g., endoscopes, disposables. These range from desktop laser welders, to compact manual laser welders, to the fully automated ExactWeld series. The end results are superior weld quality, higher production yields, better process consistency and improved operator productivity.

Our systems range from EasyMark table-top marking systems to the latest ExactMark automated series that provide the features and performance of larger and much more costly marking systems in a compact and easy-to-use platform. ExactMark is available with a USP laser to perform corrosion-resistant laser black marking on stainless steel and other metals. Alternatively, these systems are available with infrared, green or ultraviolet lasers for conventional marking of metals and polymers.

Coherent understands that superior support is just as important as superior machine performance. The company operates as a truly global enterprise which we believe is an essential requirement to fully support today’s medical device manufacturers using distributed manufacturing concepts. We operate production, sales and service sites as well as numerous full-equipped applications labs, strategically located all over the world.