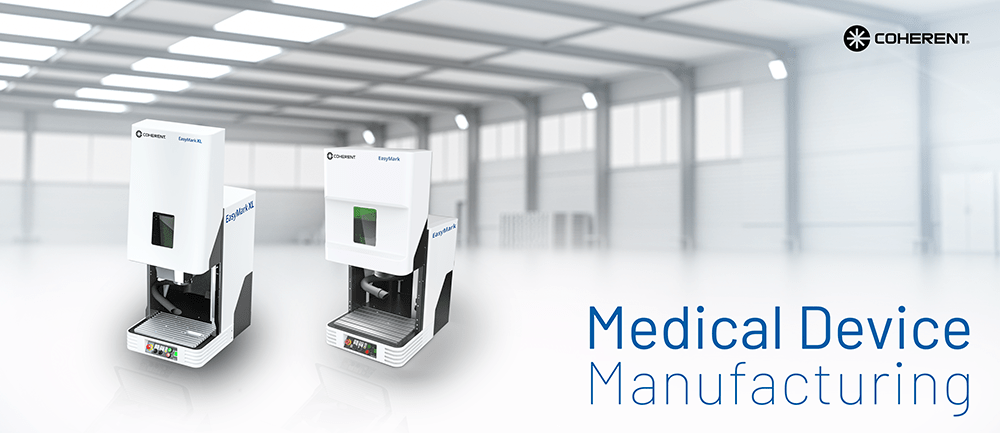

The EasyMark series, EasyMark 5 and EasyMark XL, is one of the most compact laser marking systems on the market. It is an easy-to-use, self-contained, table-top laser class 1 system for permanent vector and grayscale marking. The system is well-suited to marking steel instruments like scissors, clamps and forceps, titanium implants including screws and plates, and plastic devices that assist in handling and insertion of implants.

The EasyMark combines a fiber laser with high-precision mechanics, a moving laser head and stationary part platform. This simplifies the design of tooling to hold the part and ensures high precision and excellent mark consistency. Plus, an integrated camera system simplifies precise operator positioning of the mark. High quality galvanometer scanners, motion systems and mechanical components all ensure superior mark accuracy and consistency – a particularly important advantage when marking high-value components.

The system can be equipped with a 20 W, 30 W or 50 W fiber laser, optionally with Varia, an adjustable laser pulse width technology for precise optimization to match your workpiece material. This maximizes both the range of materials and the types of marks it can produce.

Intuitive Operation

The well-proven, intuitive industrial software in the EasyMark simplifies mark design, preview, and execution. It also easily links to external data bases, e.g., for serial number logging, process documentation, etc.

Features & Benefits

- Laser class 1 table-top laser marking system

- Easy operation thanks to user-friendly graphical user interface

- Spacious working chamber

- Low maintenance and service costs

- SmartView™ camera positioning

- Ring Marking Module RMM

More information on our website: https://www.coherent.com/lasers/laser/new-easymark