The MVI Injector is suitable for self-contained and flow-controlled delivery of gene therapies, stem cell therapies and dermal fillers

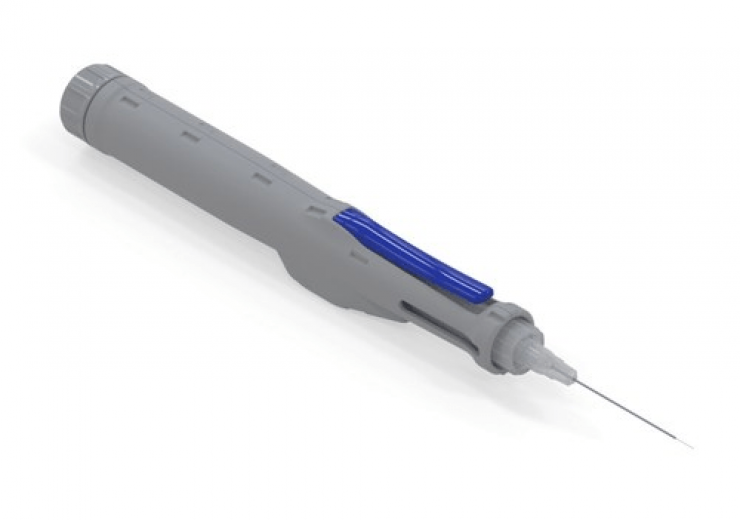

The MVI platform facilitates exacting precision and controlled dosing. (Credit: PRNewswire / Altaviz)

Altaviz, a provider of medical devices and drug delivery platforms, has launched a new handheld injection platform for the precision delivery of any fluid viscosity.

The new handheld Microvolume (MVI) Injector is claimed to be the world’s first delivery platform suitable for self-contained and flow-controlled delivery of gene therapies, stem cell therapies and dermal fillers.

It is also developed for any high viscosity fluid, which needs precision dose delivery and control.

The MVI platform will facilitate exacting precision and controlled dosing through a simple to use and self-contained handheld device. It supports adaptability in a range of applications and therapies.

Altaviz CEO Jack Auld said: “The problem is that prior to MVI, there were no methods or devices to enable this critical treatment.

“But we’ve provided a platform that could solve that. We took a full-system approach to optimize every detail of the procedure…and, we’ve now optimized it as a platform that can be adapted to other uses as well.”

According to the company, the self-powered device, which is available in a small and easy to operate form factor, can be used with single handed operation.

The high-power drive system has the potential to offer the full range of viscosities from equivalent gene therapies to the highest viscosity dermal fillers via 41ga equivalent cannulas.

Designed to offer enhanced flow control, the MVI platform delivers a consistent experience across varying downstream resistances.

To maintain drug and therapy dosing accuracy, the MVI uses fully integrated visual and audio dose feedback cues to enhance the surgeon’s ability to achieve the dose target.

The integrated dose tracking system will help continuously measure dosing with sub-microliter precision.

MVI is said to automatically record injection metrics both on-board and through external endpoints such as tablet, laptop or personal computer.

In addition, the platform uses gas-powered hydraulic drive mechanism to produce repeatable and precise delivery rates.