After 28 years of building standard and custom laser workstations for multiple applications required by customers, Mundt has built an exceptional ultra-short pulse laser workhorse that combines a Cartesian system with a galvanometer with infinite field of view to offer more options that address high-precision industrial requirements. The capabilities of these powerful multi-axis Class I or IV laser workstations provide solutions for any manufacturing need.

The DB-241218-7 Axis Laser Workstation

This is an advanced manufacturing tool, with more built-in capabilities than most other machines available on the market today. The ultra-short pulse lasers, femtoseconds to picoseconds, perform unique tasks in multiple industrial applications, particularly ablation, cutting, drilling, marking and other surface-modification processes.

Ultra-short pulse-laser energy can ablate without heat input to the part, so there is no heat-affected zone. This highspeed, seamless machining over large areas improves process times, enables more complex product designs, improves product reliability and lowers operating costs. The future requires technology changes; miniaturisation requires new manufacturing technology; and Mundt supports the new industrial demands for microelectromechanical systems.

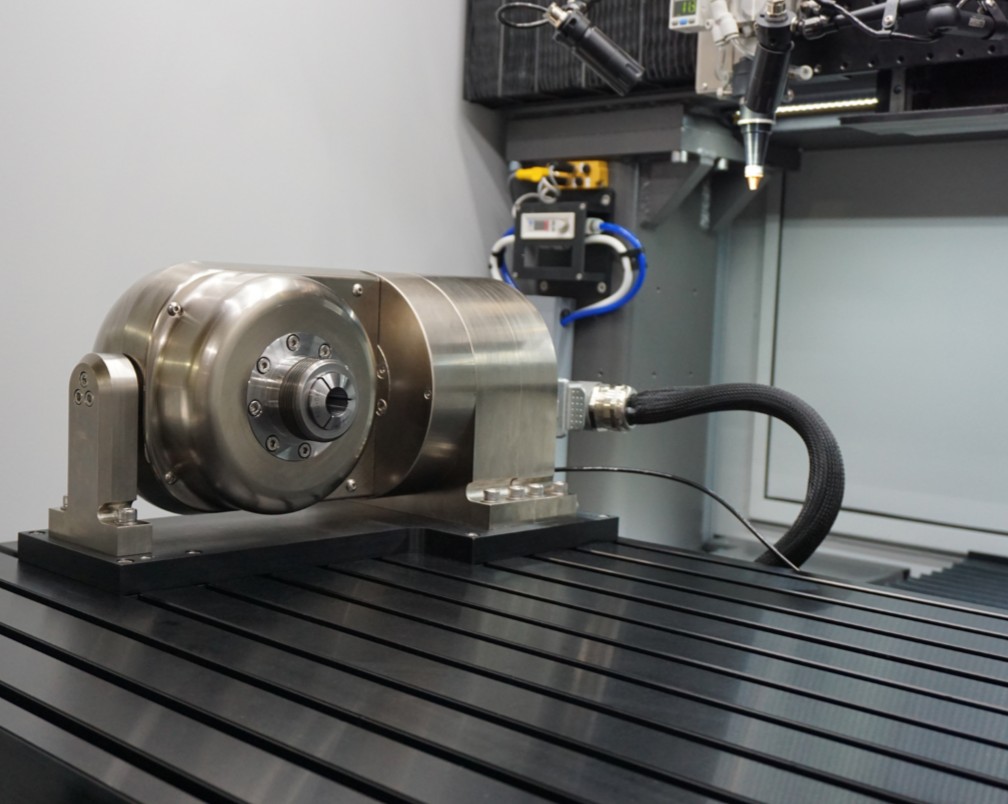

The AB-200150-5 Axis Laser Workstation

This new workstation is built on a granite/ ceramic base and achieves extreme 0.5µm of accuracy that permits machining of tiny detailed features.

Four-F optics allows precise galvanometer movements, and infinite field of view provides for accurate and seamless part programming and processing for operators.

There are several reasons to embrace laser-micromachining technology:

- Today’s advanced designs demand high throughput, accuracy, competitive pricing and support.

- Industries now require components with smaller features that demand new processing with dependable, highaccuracy technology, and it is now possible to choose the best materials for the job; for instance silicon, platinum, glass, animal tissue, kevlar, stainless steel, plastics, copper or gold. Smarter and lighter electronics are required for medical and other industries.

- Save money and get substantial ROI with high yields, more efficiency, and greater productivity. Machines pay for themselves in a short period of time, and Mundt will upgrade and service any machine for as long as they are in use.

Mundt provides laser workstations to accomplish the most complex welding, drilling, and ablation required by the medical industry, and it offers standard and custom solutions for a design team to ensure the success of any project. Mundt laser workstations are built in Scottsdale, Arizona, US.

MUNDT & ASSOCIATES, INC.

14682 N. 74th St.,

Suite 150, Scottsdale,

Arizona 85260

USA

Tel: 480-922-9365 Fax: 480-922-9341

URL: http://www.mundtinc.com/contact/