3DGence Industry F420 is a high-performance, high-temperature rapid production 3D Printer capable of printing the highest-performance polymers such as PEEK and ULTEM™™.

Key Innovative Features

- Interchangeable printing modules – print the widest range of materials in one printer from ABS to ULTEM™.

- High-Temperature printing chamber – accurate, highest-performance parts

- PEEK, PEKK and ULTEM™3D printing– the highest temperature/anti-corrosive polymers

- Total Support Material Solution – proprietary materials allow for complex geometries

- High-quality components – dedicated electronics, fast/rigid kinematic system, robust design

- 3DGence CLOUD – remote control over printing process

- Advanced air filtration, signal tower and power backup – operator safety and industrial standards

Ultra-Fast 3D Printing

The newest industrial platform from 3DGence extends the focus on speed and even more advanced materials. The INDUSTRY F420 is considerably faster than market standard, while printing the range from initial draft prototypes to final end-use parts.

The most advanced filaments like PEEK or ULTEM™ are printed at speeds that positions the INDUSTRY F420 at the top range of industrial grade 3D printers and a best-in-class total cost of ownership.

The speed, accuracy and versatility enable the customer to increase productivity in ideation and development to production process, shifting from rapid prototyping to rapid production faster while eliminating multiple inefficiencies.

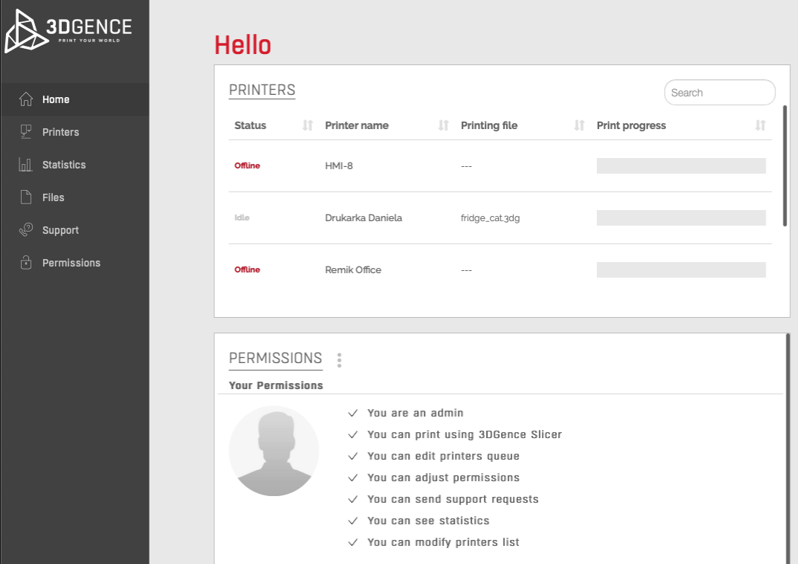

3DGence Cloud Solution

3DGence CLOUD includes services and functionalities such as administrative user access, running or queueing 3D prints, remote monitoring of the printer and print status, file sharing, live camera feed, and collection of the statistics.

The functionality that differs CLOUD from competitors is the technical support and remote service provided by 3DGence support experts.

Automatic Spool Change

Utilizing four material bays in INDUSTRY F420’s heated filament chamber, continuous printing without downtime is possible. By default, two bays are dedicated to model material and remaining two house support materials.

F420 is capable of automatic spool change mid-print. Once filament end is detected, the machine will load material from the second bay without any user intervention and resume printing seamlessly.

Automatic Nozzle Cleaning Station

With every change of the nozzle, customer is sure that the quality of print will be not influenced by contamination on the nozzle from the previous cycle.