NS Medical Devices is using cookies

We use them to give you the best experience. If you continue using our website, we'll assume that you are happy to receive all cookies on this website.

ContinueLearn More X

We use them to give you the best experience. If you continue using our website, we'll assume that you are happy to receive all cookies on this website.

ContinueLearn More XProduct

March 31, 2021

Medical screws have important jobs to do. They attach spinal cages to treat ailments like lumbar scoliosis, affix intermedullary (IM) nails to bones to treat femoral, tibial, humeral, and trochanteric fractures, and screw directly into smaller broken bones to help them heal.

For over 20 years Tegra Medical has had the important job of manufacturing many types of medical screws, particularly those that are highly complex and implanted in the body.

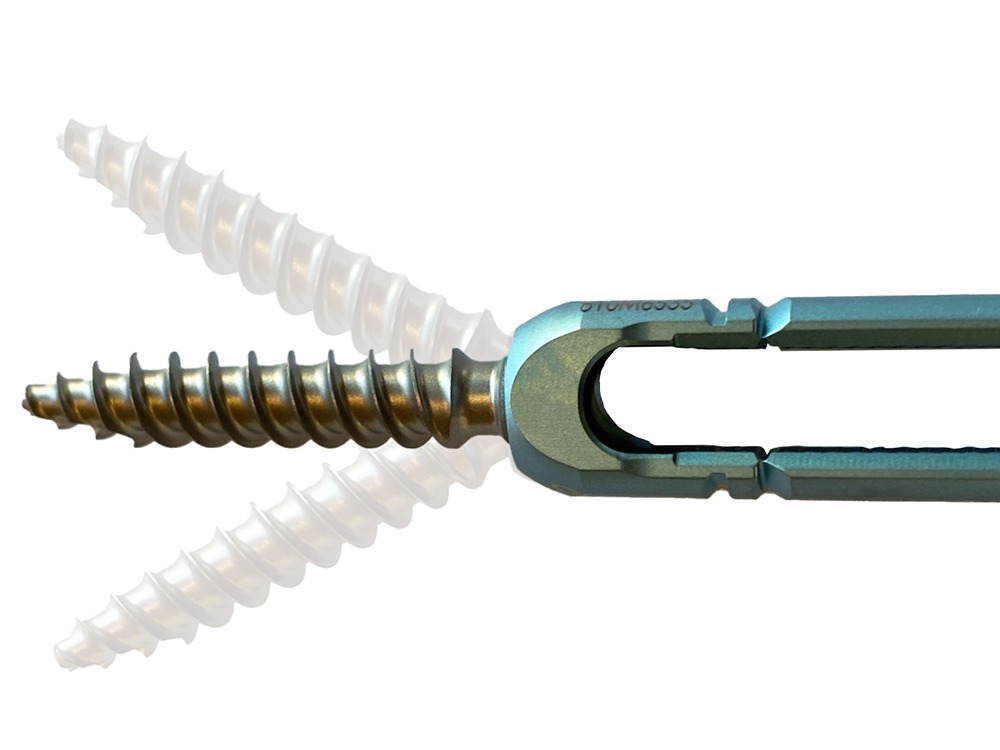

Take a titanium polyaxial screw, for example, which is used to connect vertebrae rods in spinal surgery such as spinal fusion procedures. Tegra Medical manufactures the entire screw and its assembly. The screw’s head is enclosed in a housing that allows the screw a range of motion along several different axes relative to the housing (see the image). This movement allows a surgeon, who is working within the constraints of a small incision, to fasten the screw at the proper angle during surgery. The long shafts are designed to be removed after the screw has been implanted.

If a polyaxial screw is not manufactured correctly, it won’t be secure in its housing, which causes unnecessary frustration for the surgeon trying to focus on a delicate procedure. Tegra Medical’s decades of experience making spinal implants has given us the know-how to make and assemble the parts to they function flawlessly.

Tegra Medical won’t get bent out of shape turning your complex screws.