The flexibility of the Scanner Optic to create any welding trajectory at high speeds without separate motion control has given it some recognition in the industry. Inside the Scanner, two pivoting mirrors deflect the laser beam in X and Y direction to follow a pre-defined path programmed in G-code. The adapted focusing lens (f-theta) determines the size of the working area, the diameter of the laser spot created, and the focal distance. The three most common lenses used with the Scanner provide an operating field of 100×100 mm, 240×240 mm, and 350×350 mm.

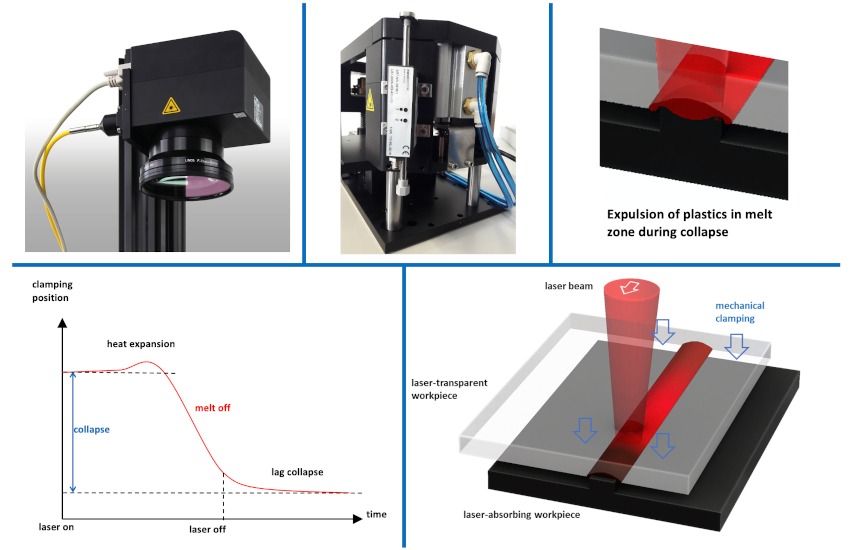

Although a Scanner Optic can be used to perform a Fast Contour welding operation, in general, it adds more value when used to perform a Quasi-simultaneous Process. Because the laser beam can trace the weld path at high speeds, it makes more sense to do multiple passes over the welding area at higher laser power. The result of heating the entire welding area of the parts almost simultaneously gives the opportunity to gradually melt the material and overcome uneven surfaces molded with the option to collapse. Like other welding technologies, the collapse can be analyzed for quality evaluation or process control.

Thanks to a modular design and adaptability, the Scanner Optic can be integrated into the Turnkey S, Turnkey M, and the Modula Assembly Inline platforms. Also, it can be included as a key component with the Modula Assembly Lab or as a separate component for custom machine integration.