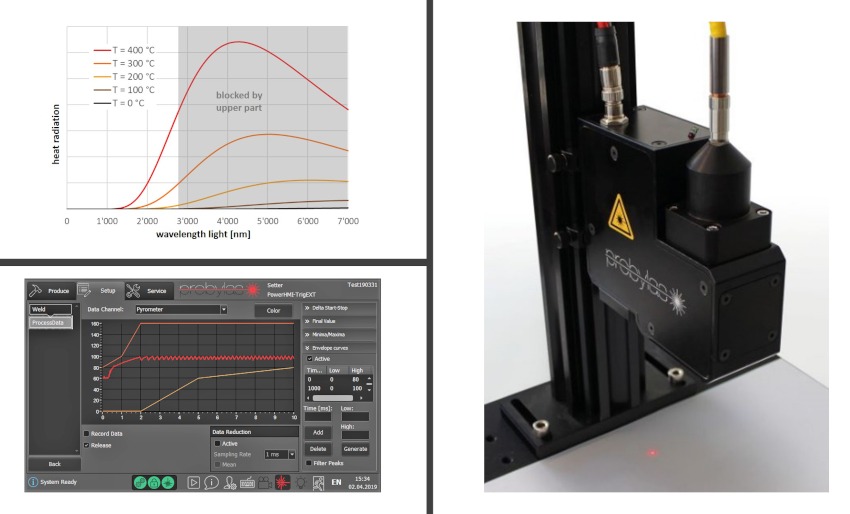

In pyrometry, a remote sensing thermometer retrieves infrared radiation from the melting area during the weld. In principle, the sensor focused on the interface detects the infrared wavelengths transmitted by the upper part. Because the weld occurs between the two layers, the reading quality will depend on how transmissive the upper part is. Thus, the signal collected can then be analyzed and compared to a known value for quality control (open-loop), or the incident laser power is adjusted for temperature control (closed-loop).

This pyrometer sensor is built-in the Advanced Spot Optic platform. One electronic board inside the optic amplifies, detects, and converts the signal to communicate with any control unit from the ProByLas’ product portfolio. This sensor monitors the relative temperature in the material on emitted infrared radiation at the welding point every millisecond. The Pyrometer is calibrated from the factory to operate in conjunction with a specific optic head, fiber, and laser diode.

This technology is commonly used to control the quality and repeatability of the weld. Those pyrometer readings that behave differently to pre-validated values and fall out of the standard envelope can be regarded as a defective weld. When used as a closed-loop control, the pyrometer can dynamically increase or decrease the power output of the laser diode to maintain the known relative temperature during the weld and avoid quality inconsistencies. Likewise, these readings can help determine if there is a problem with the setup, material, or production tooling.