The OH02B image sensor is built on the company’s PureCel Plus‑S stacked-die technology

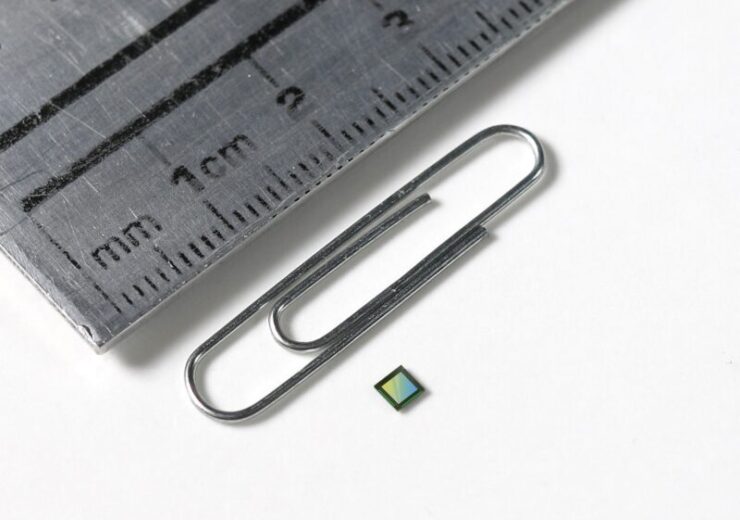

OMNIVISION’s OH02B image sensor. (Credit: OMNIVISION)

Imaging technology producer OMNIVISION has unveiled the OH02B image sensor, a square two-megapixel (1500 x 1500) resolution CMOS image sensor for reusable and disposable endoscopes, catheters, and guide wires.

The OH02B image sensor is built on OMNIVISION’s latest PureCel Plus‑S stacked-die technology. It can be used on endoscopes for gastrointestinal, orthopedic, ENT, surgical, dental, and veterinarian purposes.

According to the firm, it is offered in the smallest form factor, the 2.5 x 2.5mm CameraCubeChip package (OCH2B), for disposable designs.

It has OMNIVISION’s AntLinx technology, which offers a 4m interface connection directly from the endoscope camera to the camera control unit (CCU) tower by using four thin micro-coaxial cables.

The US-based firm said that the AntLinx technology provides enhanced video quality and minimises interface conversion requirements for long-reach applications such as gastrointestinal endoscopy. It also has minimal electromagnetic conduction and is not affected by noise or electromagnetic interference.

OMNIVISION senior marketing manager Richard Yang said: “The medical industry is moving to single-use endoscopes to minimize cross-contamination and improve patient safety.

“CCD-based image sensors cannot meet today’s high-performance endoscope requirements and are being phased out.

“CMOS image sensors, such as the OH02B, are critical for the disposable endoscope market because they enable high resolution and small size, generate very low heat at the tip of the scope design, and are cost-effective for one-time use.

“OMNIVISION’s CameraCubeChip design provides further size advantages and simplifies design resources and the supply chain.”