Sensera general manager and microdevices chief operating officer Tim Stucchi said: “We have focused on medical device component fabrication and assemblies over the last two years and this certification solidifies our support of our customers’ quality requirements. Achieving this standard recognizes our investments in our quality systems, our people and our customers.”

Sensera CEO Ralph Schmitt said: “Sensera is well-positioned, due to significant experience in manufacturing components for our medical customers where a microsensor, microfluidic channel or specialized assembly is incorporated into the diagnostic or medical system.

“ISO 13485:2016 is the affirmation of processes we have built in-house supporting our growing medical segment, and it is a true reflection of our long term focus in this market.”

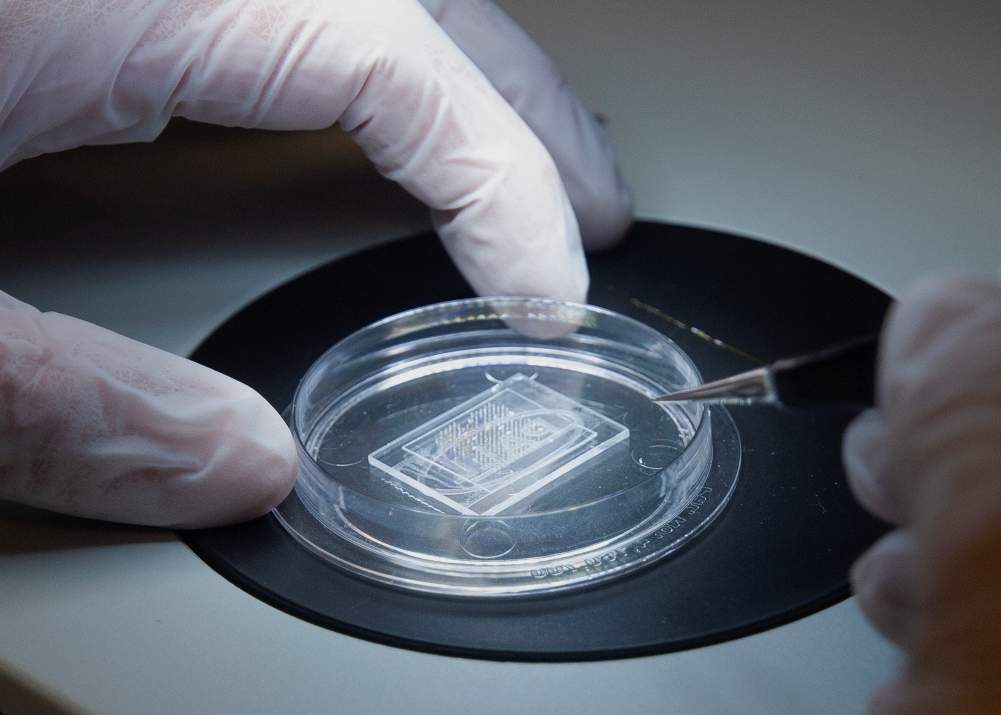

Sensera previously achieved ISO 9001:2015 certification last year, and differentiates itself as a bespoke MEMS / microfabrication provider. Sensera makes products such as pressure sensors on a wafer level that are used in vivo, but also integrates these sensors into sub-assemblies to allow its customers ‘plug and play’ integration into their life saving products.

Stucchi said: “As a part of our commitment to our growing customer base we embarked upon the ISO path aggressively and are extremely proud to have attained certification in less than 12 months.

“Sensera has been determined to build quality into our manufacturing processes since day one, and have thus been able to achieve both ISO 9001 and ISO 13485 certifications in little more than a year.”

MiniFAB chairman & acting CEO Michael Wilkinson said: “I’d like to congratulate Sensera on recently passing their ISO 13485 audit. Sensera’s wafer materials and processes play an important role in a number of products that we’ve developed. Their ISO 13485 accreditation will help further expand the opportunities to collaborate and innovate together in the future.”

Micro-ElectroMechanical-Systems (MEMS) is an innovative technology used to make miniaturized mechanical and electro-mechanical elements that are employed in medical devices through microfabrication techniques. According to Stratistics Market Research Consulting, the rapidly growing (18.7% CAGR) global MEMS medical device market is expected to reach $10.4bn by 2022.

Source: Company Press Release.