ivWatch worked from the beginning to develop a pinnacle surgical N95 respirator made in the USA, with locally sourced materials, and manufactured at the company's domestic FDA registered facility

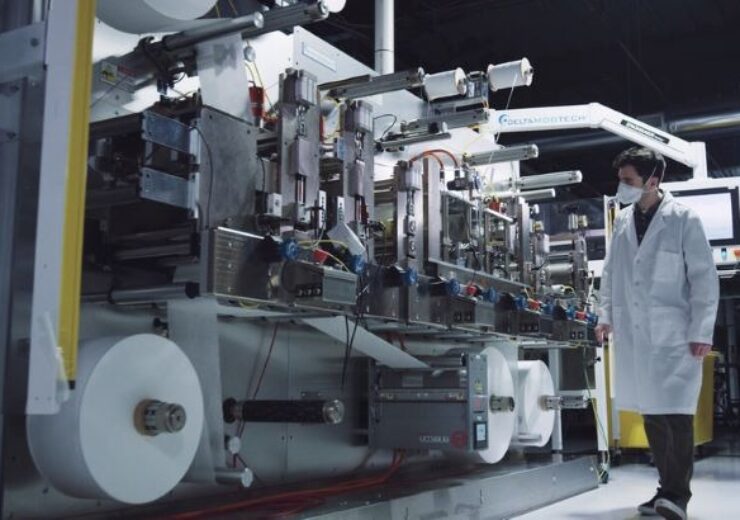

ivWatch manufactures blox Surgical N95 Respirators, under approval number TC-84A-9379, at the company’s Hampton Roads headquarters. (Credit: PRNewswire / ivWatch, LLC)

Today, ivWatch, LLC, a leading medical device manufacturer of biosensors that detect IV infiltration and extravasation events, received approval from the National Institute for Occupational Safety and Health (NIOSH), a part of the Centers for Disease Control and Prevention (CDC), to produce surgical N95 respirators. The new designation allows ivWatch to produce blox Surgical N95 Respirators, under approval number TC-84A-9379, at the company’s Hampton Roads headquarters to help close the gap in the surgical N95 respirator shortage. Unlike industrial-use N95 respirators, surgical N95 respirators are designed and tested specifically for medical and healthcare use.

ivWatch worked from the beginning to develop a pinnacle surgical N95 respirator made in the USA, with locally sourced materials, and manufactured at the company’s domestic FDA registered facility. BLX-9501 underwent extensive sourcing requirements and as-made performance testing to ensure the highest of quality and standards in compliance with 42 CFR 84. The company was awarded NIOSH designation following a year-long development and application process as well as third-party validation testing from Nelson Labs and Pacific Biolabs. ivWatch has an established Quality Management System (QMS) that has been globally certified to ISO 13485 under the MDSAP program since 2018. An effective QMS is a critical aspect to any reputable medical device organization.

“We are proud to be one of only a handful of U.S.-based, authentic manufacturers to receive surgical N95 respirator designation from NIOSH,” said Gary Warren, President and CEO of ivWatch. “Our company’s foundation in engineering and mathematics allowed us to leverage our biosensor machinery to effectively create a new safety solution that can play a major role in protecting our communities. Just like we put seatbelts on when we get into a car, we are entering a time where a call for better respirators as the standard for safety and protection is necessary for our hospital systems; our respirators should put counterfeit, inferior N95s in the rearview mirror.”

The designation comes as countries, states, municipalities, hospitals, airlines, and retail stores across the globe are re-evaluating or, in some cases, re-establishing mask mandates. Some are even taking it one step further and banning subpar cloth masks. Hospitals in parts of the country are also continuously in need of valuable, authentic PPE as they reach ICU capacity or anticipate influxes of highly contagious patients.

“Our manufacturing, quality, and regulatory teams have been working rigorously with NIOSH – from concept to design to final production – to gain surgical N95 respirator approval. Considering we are two years into the COVID-19 pandemic, we’re honored to be approved by NIOSH at a critical time where high-filtration respirators could be the catalyst in turning the tide against this lethal pandemic across the globe,” said Jaclyn Lautz, PhD, Chief Operating Officer at ivWatch.

blox products are backed by the vQuality system, an interactive database designed to combat poor quality and counterfeit respirators that have flooded the market. vQuality exposes the inline testing performance data from each lot of respirators. The blox Surgical N95 Respirator was analytically tested to comply with industry standards. The need for reliable, authentic, comfortable, and affordable respirators for hospitals remains.

blox Surgical N95 Respirators are tested to ensure greater than 95% filtration efficiency1 and are built for extended wear times with a comfortable, secure fit and a 360-degree seal. blox Surgical N95 Respirators meet CDC guidelines for tuberculosis exposure control and are fluid resistant – critical requirements for respirators approved for medical, surgical, and clinical environments.

In the research and development phase, blox’s unique pleated design was specifically engineered and manufactured to pass hospital fit testing protocols. blox Surgical N95 Respirators were third-party tested by Nelson Labs. Performance test results include:

Synthetic blood penetration resistance up to 160mmHg per ASTM F1862

Inhalation resistance (complete respirator): 7.3 (mm H2O)

Exhalation resistance (complete respirator): 9.4 (mm H20)

Flammability rating: Class I per 16 CFR 1610

Source: Company Press Release