A new biomaterial from Evonik speeds up fusion over the boundary between bones and implants using biphasic calcium phosphate - an additive bone substitute

Evonik has been developing PEEK-based materials for more than 20 years (Credit: Evonik)

German speciality chemicals firm Evonik has unveiled a new ‘one-of-a-kind’ biomaterial for use in medtech applications.

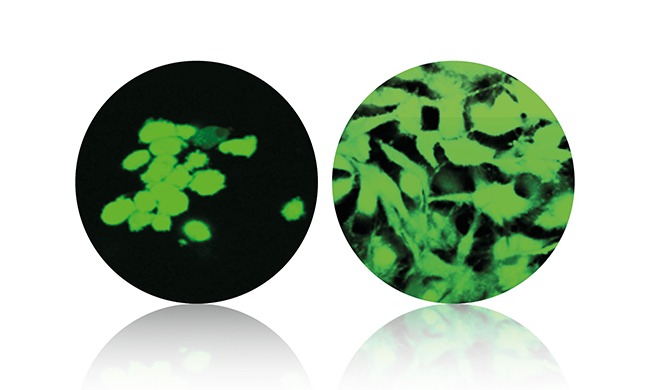

The osteoconductive PEEK (polyether ether ketone)-based implantable material is designed to speed up the fusion between human bones and implants.

The company claims these osteoconductive properties – which mean it can serve as a scaffold allowing new bone cells to attach and grow over the boundary to an implant – were achieved using an additive bone substitute called biphasic calcium phosphate.

By helping bones and implants in the body to fuse more quickly, this also enables quicker recovery times for patients following surgical procedures.

Evonik unveiled its new biomaterial at the virtual Eurospine 2020 conference, which is taking place from 6-9 October, and will now launch a line of next-generation, PEEK-based materials under the brand name VESTAKEEP Fusion.

Marc Knebel, head of Evonik’s medical systems market segment, said: “Introduction of the new VESTAKEEP Fusion product line represents an important step in the strategic development of our portfolio.

“This work draws upon our decades of expertise in polymer chemistry and on Evonik’s global innovation and production network.

“That foundation means we can offer patients a one-of-a-kind product and significantly improve their quality of life.”

How is the new Evonik biomaterial manufactured?

Evonik claims its VESTAKEEP Fusion material has been developed for a variety of production technologies, and will come as both a granulate and a semi-finished stock-shape product.

Like all of the company’s previous PEEK products – an area it has worked and manufactured in for more than 20 years – the newly-unveiled material can be milled, compression moulded, and extruded.

VESTAKEEP Fusion can also be injection moulded and has been “specially designed” so that the functional biphasic calcium phosphate additives are available on the surface, and no film formation occurs.

In collaboration with Swiss plastics engineering firm Samaplast, Evonik said it has successfully demonstrated, documented and proven the processing characteristics of VESTAKEEP Fusion in injection moulding.

Evonik’s polymer experts are also studying the possibility of developing a 3D-printable filament with its new PEEK-based biomaterial that could be processed using fused filament fabrication (FFF) – a form of production involving additive manufacturing technology.

The first biomaterial the company will introduce as part of its new product line is VESTAKEEP iC4800 – which possesses “outstanding mechanical properties” – and Evonik will offer to develop exclusive, tailored materials for its customers using VESTAKEEP Fusion as well.