The new Silbione Biomedical HCRA M500 series has been designed for applications implanted in the body for longer than 30 days

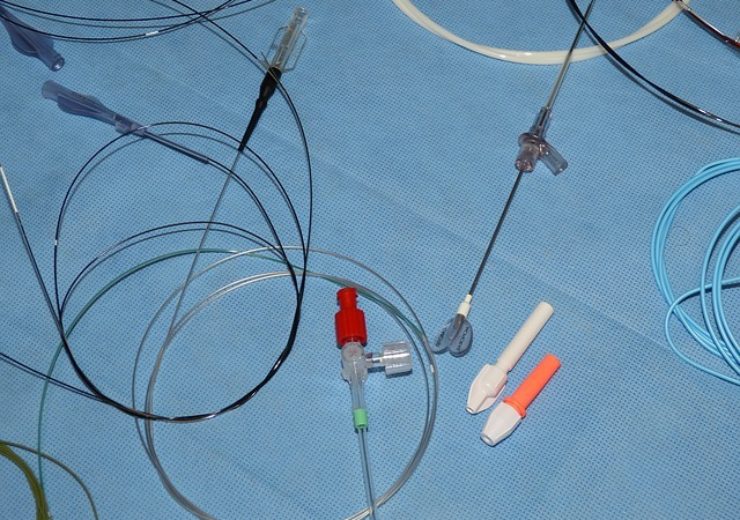

Image: Silbione Biomedical HCRA M500 series is suitable for extruding multi-lumen, co-extruded, braided, pump and thin wall tubing.

Elkem has expanded its long-term implantable silicone product portfolio with the introduction of new Silbione Biomedical HCRA M500 series.

The new heat-cured rubber (HCR) product line offers high tear strength for demanding implant applications, and facilitates easy processing for improved productivity.

Developed for applications implanted in the body for longer than 30 days, Silbione Biomedical HCRA M500 line can be used for extruding multi-lumen, co-extruded, braided, pump and thin wall tubing.

According to the company, end product examples may include ports, catheters, wound drains, stents, and shunts for a wide range of implantable medical intervention solutions.

Silbione Biomedical HCRA M500 series is available in 20 to 80 Shore A (ShA) hardnesses

Silbione Biomedical HCRA M500 series, which is available in 20 to 80 Shore A (ShA) hardnesses, is produced and packaged in certified and accredited ISO 8 and ISO 7 clean rooms in York, South Carolina.

The implant grade series is promoted by Master Files (MAFs) with the Center for Devices and Radiological Health (CDRH).

The company is exhibiting its full line of Silbione Biomedical long-term implantable silicone solutions at the Medical Design & Manufacturing Minneapolis conference, being held from 23 to 24 October.

Elkem Silicones Americas healthcare market manager Michael Goglia said: “Elkem Silicones is continuously investing in advanced materials to meet the growing market needs and help customers deliver the next generation of high-quality medical devices.

“Now, customers can have a high tear strength implantable HCR material that is easy to process and can improve productivity with faster line speeds.”

Elkem Silicones, a division of Elkem ASA, offers a range of silicone technologies for diverse speciality markets such as aerospace, automotive, construction, consumer goods, energy, healthcare, paper, personal care and textiles.

The company operates nine multi-functional manufacturing sites and 11 R&D centres across the world.

In October this year, Switzerland-based research institute and university Ecole polytechnique fédérale de Lausanne (EPFL) announced that a team of scientists from its Laboratory for Soft BioElectronic Interface (LSBI) has developed a conformable, electrode implant that enables people with dysfunctional inner ear to hear again.