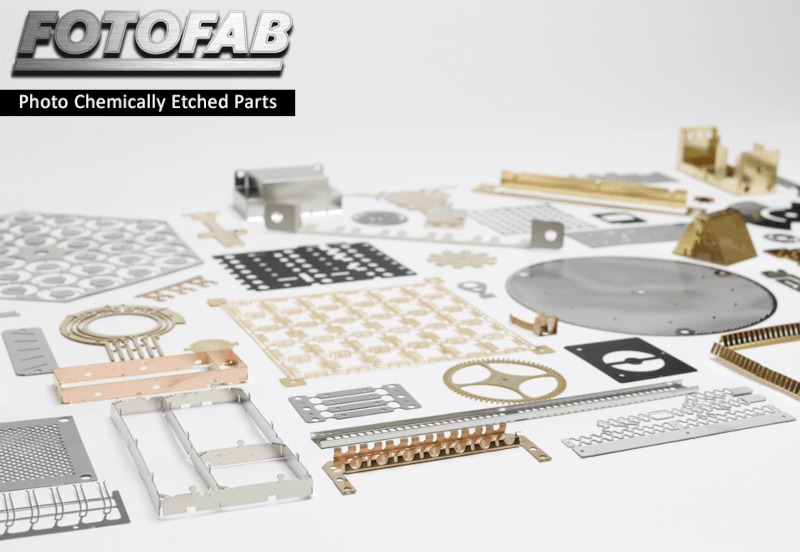

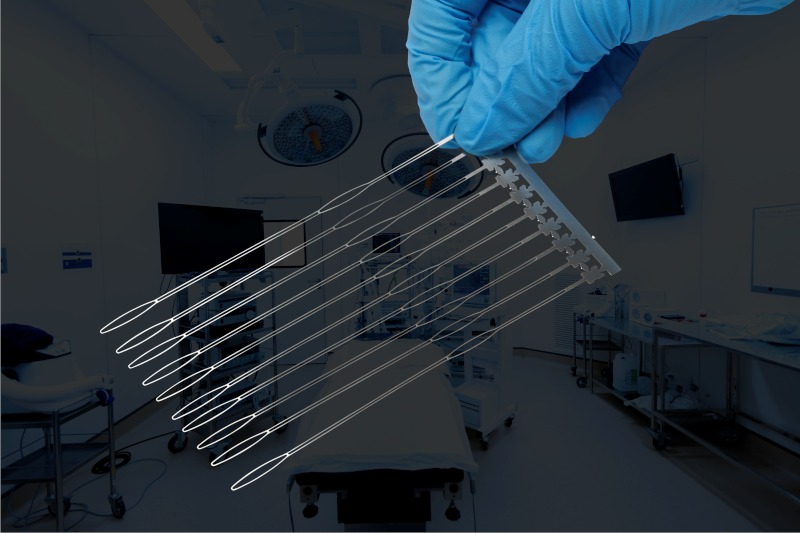

Since 1967, Fotofab has been fabricating custom metal components for innovators in the medical device and implantable industry. Leading medical companies choose Fotofab because of our tight tolerances, quick lead times, and ability to adapt fast. Our process of photochemical machining (also known as chemical etching) allows us to achieve exact to requirement parts and enables us to grow from prototype through production seamlessly.

Manufacturing Components for Medical Devices

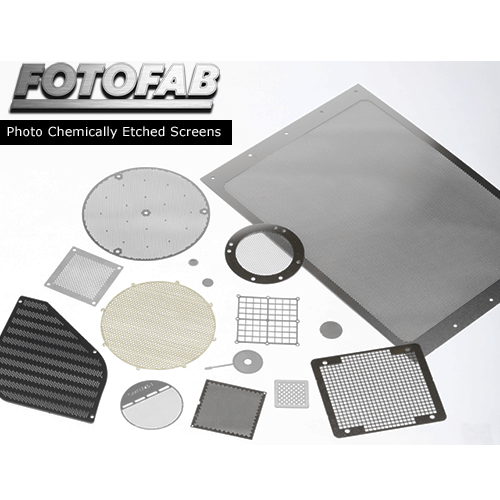

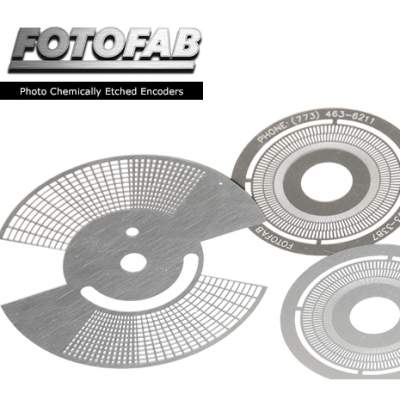

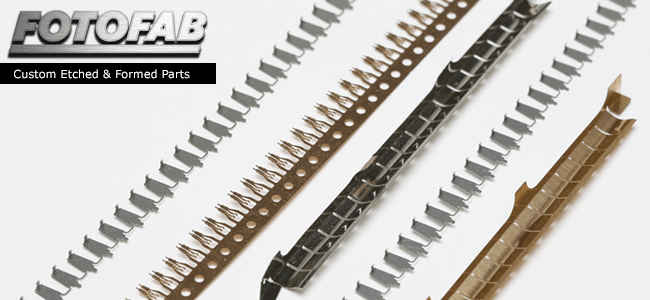

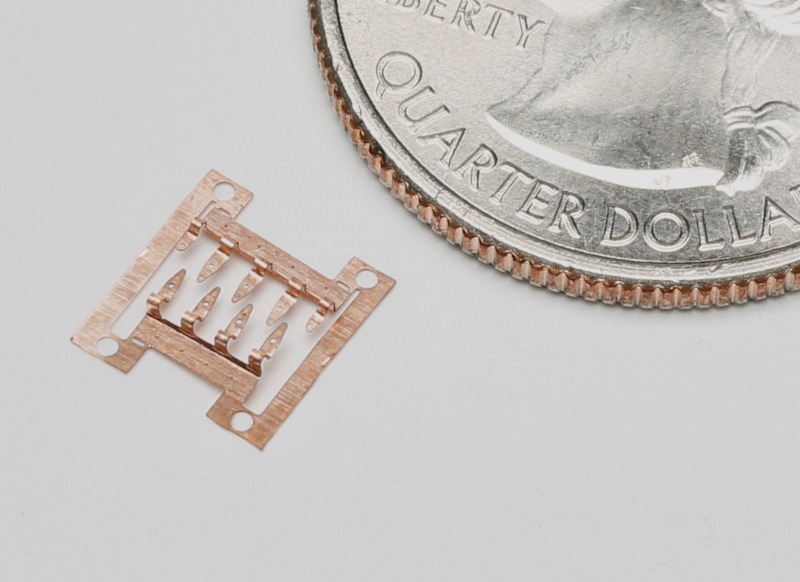

Fotofab fabricates custom parts from a long list of metals and alloys including, Titanium, Stainless Steel, and Elgiloy. Metal parts manufactured with the etching process are produced in sheets up to 24 x 36 inches and can be turned around in as little as one day. We have a minimum order quantity of two sheets, making prototyping and R&D fast, easy, and cost effective. Depending on the part design, we can manufacture parts ranging in thickness from 0.0002 to 0.125 inches with extreme precision.

Value-Added Services Offered

Along with custom etched components, Fotofab offers a variety of finishing services. Common requests include forming, electropolishing, and heat treating. Depending on the feature requirements, finishing services are available on most Fotofab manufactured parts. We will work hard to deliver your components complete and ready to use.

Fotofab’s Quality Guarantee

We strive for superior service from drawing to delivery and are committed to the highest quality of metal etching services. Our experienced engineering team has an average of 10+ years at our company and is well equipped to guide you from idea to product. Fotofab is ISO 9001 and AS9100D certified, ITAR registered, and RoHS compliant (available upon request).

We want you to trust us to do what we say and honor what we said. Make Fotofab a part in your plan.

Fotofab, LLC

3758 W Belmont Avenue, Chicago, IL 60618

866-279-5185

CONTACT US: www.fotofab.com/office-location

WEBSITE: www.fotofab.com