N2 Biomedical’s proprietary Ti360 coating improves the osseo-integrative and anti-microbial properties of polyetheretherketone (PEEK) implants.

PEEK has increasingly been used as an implant material for orthopedic and spinal devices, in part due to its inherent properties such chemical inertness, radiolucency, and an elastic modulus that is closely matched to natural bone. Despite these advantages, a major limitation of untreated PEEK implants is their hydrophobic surface which leads to relatively poor bone tissue attachment as compared to titanium-based devices.

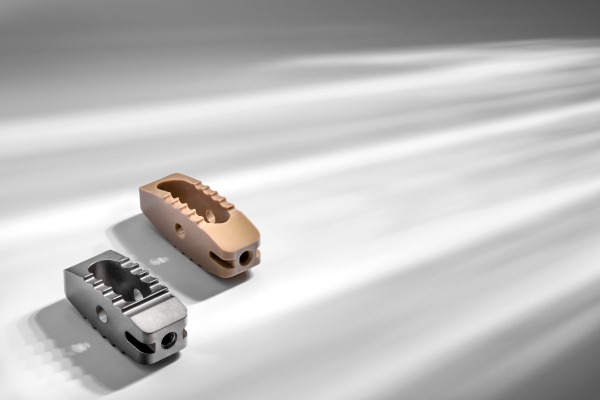

N2’s proprietary nano-engineered Ti coatings on PEEK can promote and increase new bone growth and provide a preferred track for the formation and attachment of bone tissue on selected areas of PEEK implants. N2’s nano-scale surface texturing process also improves antimicrobial properties while maintaining excellent osseo-integration.

N2’s Ti360 coating is applied with an Ion Beam Assisted Deposition (IBAD) technique, which deposits a highly adherent thin film using a low-temperature, vacuum coating process. This process combines evaporation with concurrent ion beam bombardment in a high vacuum environment. Unlike conventional Physical Vapor Deposition (PVD) coatings, which rest only on the surface, the concurrent ion bombardment intermixes coating and substrate atoms and significantly improves adhesion while permitting control of morphology, density, stress level, crystallinity, and chemical composition. The ion bombardment also eliminates the columnar microstructure often observed in conventional, low temperature physical vapor deposition to create very dense, adherent film structures.

Applications

- Spinal interbody cages

- Dental implants and PEEK archwires

- Fixation screws, pedicle screws and interference screws

- Small joints

- PEEK hip & knee implants

Substrates

- PEEK

- Stainless steel

- Cobalt-chromium

- Titanium