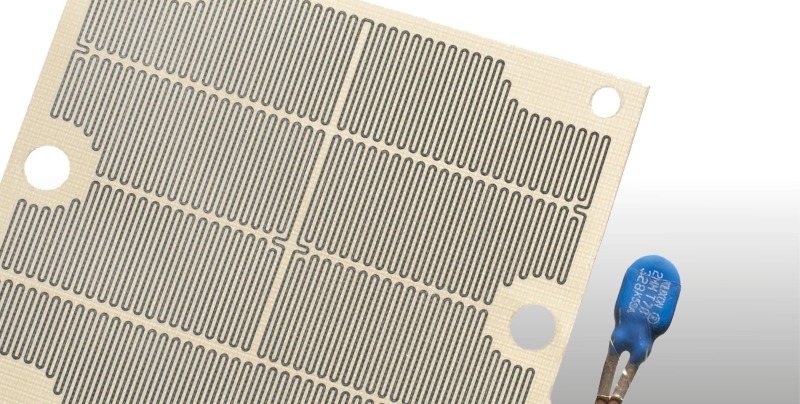

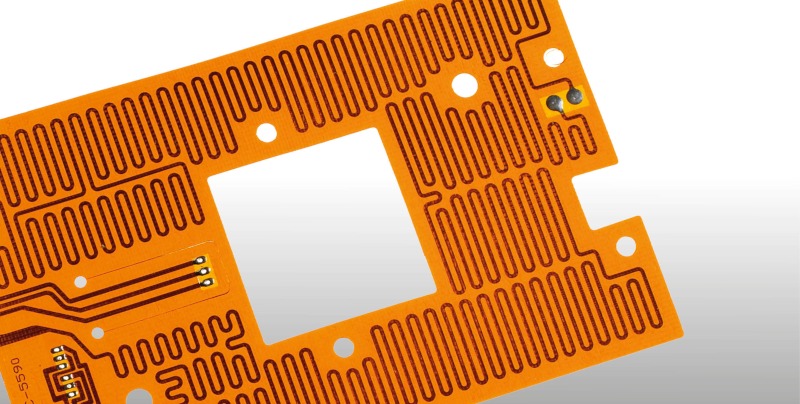

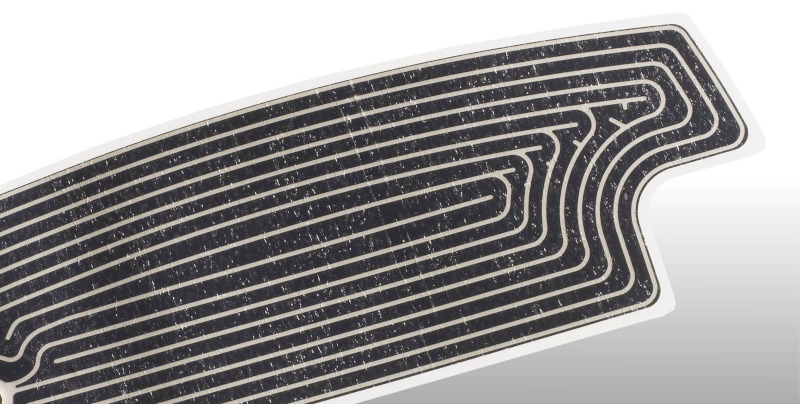

Material selection is extremely important when trying to obtain the perfect temperature and to ensure the heater works to its specific needs. We use over 25 different materials to etch your heaters onto.

POLYESTER – ETCHED FOIL Superior heat transfer and uniform heat output. Fast warm up with long life cycle. Max. power density: 0.6W/cm² Max. temperature: +105°C Mirror heaters

PRINTED POLYMER Low power, constant wattage with a large span of resistivity. Insensitive to small damage. Max. power density: 0.1W/cm² Max. temperature: +70°C High voltage, small area applications

POLYIMIDE Thin and semi-transparent with excellent dielectric strength. Resistant to chemicals. Max. power density: 1.3W/cm² Max. temperature: +200°C

MICA High power density. Fast warm up and high working temperatures. Max. power density: 5W/cm² Max. temperature: +600°C Food service appliances / Semiconductor industry / DNA analysis / Radiators, heating panels / Packing/strapping/sealing equipment

PVC Very flexible, waterproof and acid resistant with high mechanical strength. Max. power density: 0.1W/cm² Max. temperature: +70°C

SILICONE Excellent temperature properties. Can be vulcanized to metal parts. Max. power density: 1.3W/cm² Max. temperature: +230°C Food service equipment / Medical respirators / Ultrasonic cleaners / Freeze protection and condensation prevention

PEN PEN is similar to PET but has higher chemical, thermal, mechanical and electrical properties. More cost effective compared to polyimide. Max. power density: 1W/cm² Max. temperature: +160°C

PTC PRINTED POLYMER Self-regulating, robust and corrosion resistant with PTC characteristics. Max. power density: 0.3W/cm² Max. temperature: +70°C