The Wyss Center and Swiss tech firm Coat-X will collaborate to bring the new ultra-thin coating for medical implant devices to the market

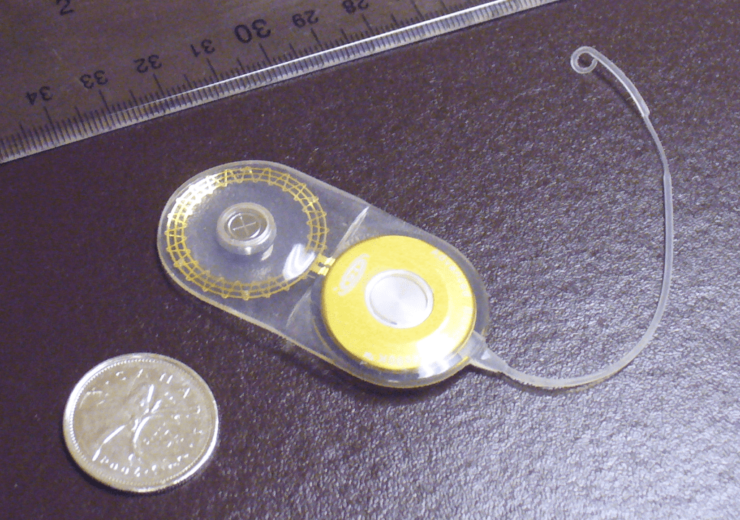

Cochlear implants are one of several types of implantable devices that could be miniaturised - while remaining leakproof - using the new ultra-thin coating (Credit: Wikimedia Commons)

A new ultra-thin, flexible coating will make it possible for implant devices to be miniaturised in the future – according to the team behind this technology.

The Wyss Center, a Geneva-based research foundation, and Swiss tech firm Coat-X announced today they will collaboratively bring the biocompatible coating to the market for use in medical implants, such as cardiac pacemakers, cochlear implants and neural monitoring devices.

These devices contain electronics that must be protected from warm, wet, and salty environments inside the human body – which often means using more conventional glass, ceramic or titanium coatings that are thick and rigid to ensure they survive and stay functional for longer.

However, the Wyss Center and Coat-X claim that, because it is just 10 microns thick, their new coating can encase miniature, implantable electronics directly in a leakproof envelope, and is also flexible enough to conform directly to the shape of an electronic device.

George Kouvas, chief technology officer at the Wyss Center, said: “Despite advances in the microfabrication of electronics, active implants today still have relatively large volumes.

“This is mainly due to the limited scalability of traditional medical implant housing technologies – the electronics may shrink, but this is not the case for their housings.

“Our partnership with Coat-X will validate the use of a new, thin-film coating technology, paving the way for the miniaturisation of medical implants and enabling a future where very small medical devices are seamlessly integrated with the human body.”

New ultra-thin implant coating

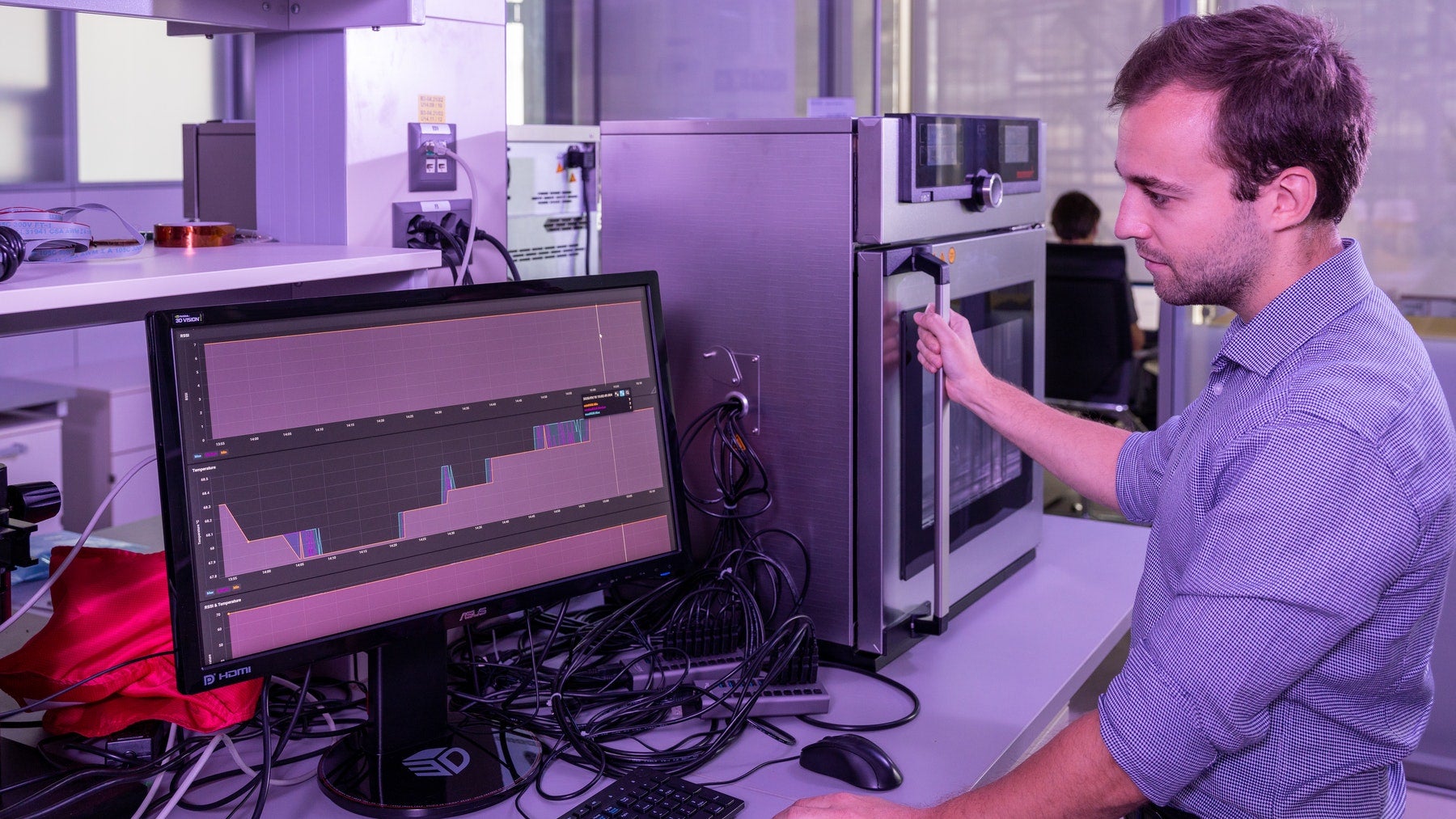

The team behind this new ultra-thin, biocompatible coating will now apply several variations of it to prototype devices, before subjecting them to high temperatures and humidity to accelerate its ageing, and observe how it’s likely to be affected by conditions in the human body over time.

Electronic tags built into these prototypes devices will wirelessly send updates to the team on the internal status of the electronics they hold.

This will allow the Wyss Center’s electromechanical team and engineers from Coat-X to continuously assess the hermeticity – or airtightness – of the new coating.

The Wyss Center’s CEO Dr Mary Tolikas said: “If we can validate that Coat-X’s ultra-thin coating has favourable barrier and durability properties in the long term, we will further our collaboration to bring this technology to market and, hopefully, enable even smaller medical devices to be implanted in patients around the world.”