GS1 Ireland, a not for profit organization, has led an international coalition which successfully employed a sterile field scanner during surgery.

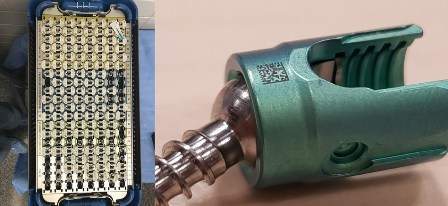

Image: Hospital Sterilised implants. Photo: courtesy of PRNewsfoto / GS1 Ireland.

The TRACTUS scanner by Matrix IT Medical Tracking Systems effectively collected detailed medical device information from extremely small codes known as data matrix codes on hospital-sterilized implants at Wheeling Hospital in West Virginia, USA.

For the first time, full medical device traceability was proven on these implants, allowing for future device analytics.

Patient injury and death motivated governments worldwide to pass laws requiring medical devices be traced through their life cycles. Known as Unique Device Identification (UDI), a substantial barrier to compliance is the inability to fully identify hospital-sterilized devices.

GS1 Ireland industry engagement and solutions manager Alan Gormley said: “Many implants and surgical instruments are removed from their packaging, placed into trays and sterilized in the hospital.

“The surgeon typically uses only what is needed, and the rest are returned to be re-sterilized for another surgery. Once placed into trays all detailed information from the package label can be permanently lost.

Mike Schiller, Senior Director of Supply Chain for the Association for Healthcare Resource & Materials Management-a professional membership group of the American Hospital Association-has been working to solve challenges associated with UDI documentation.

Schiller said, “for these devices, fast, accurate and complete traceability is a must, but has been a significant challenge for hospitals.”

Further complications include the inability to identify how many times these devices were used on patients and/or re-sterilized so that they may be safety checked. Many of these devices may have been sterilized or used hundreds of times.

The aim of the coalition of top worldwide healthcare stakeholders known as ‘Blueberry Castle’ (BBC), is to analyze the speed and accuracy of numerous documentation methods for surgical implants. From this data, a “best practices” guide for manufacturers and hospitals is being created.

AHRMM participates in the Blueberry Castle project and hosts and convenes several Learning UDI Community workgroups designed to solve challenges in UDI adoption. Schiller said, “AHRMM is excited to be a part of this project and looks forward to seeing continued success in this arena.” He said, “UDI adoption has the potential to reduce healthcare costs while improving patient outcomes in the long term.” Schiller stated, “hospital sterilized medical device documentation has been a challenge, but one we are solving.”

Prior simulated surgery pilot results at Wickenburg Community Hospital in Wickenburg Arizona concluded that only two methods could collect all medical device information, including lot numbers, expiration dates and serial numbers.

Richard Wedig, Chief of Clinic and Surgical Services Officer at Wickenburg Hospital said, “other documentation methods were shown to be error prone, could slow down surgery and could not document detailed implant information.” Wedig said “We found there are only two methods to collect the UDI during surgery; packaging scanning and sterile-field scanning.”

Scanning UDI placed onto packaging requires two staff members. One is usually the circulating nurse, who is responsible for patient safety during surgery. The circulator is diverted from his or her primary patient safety task each time he or she must search for the exact package from a large cart of implants, verify the package integrity, scan the label, open the package, drop the implant onto a sterile table.

Once the device is placed onto the sterile table, the surgical scrub technician retrieves it, loads the device onto a tool and hands it off to the surgeon. “While this is occurring, the surgeon is waiting,” said Mitch Wagner, MD., orthopaedic surgeon at Wickenburg Community Hospital.

The Association of periOperative Registered Nurses (AORN) is the leader in advocating for patient safety and excellence in perioperative practice and healthcare. As a coalition participant, AORN noted that challenges were identified with manufacturer sterilized packaging and has advocated for full UDI documentation prior to implantation.

Those challenges require large amounts of storage space, have potential sterile packaging failures, and increased surgical times while the patient is under anesthesia.

The second option is for manufacturers to laser mark the UDI directly onto each implant via very small data matrix codes. Each device is placed into trays that are sterilized before surgery and positioned into the operating room sterile field.

The scrub technician removes the correct device from the tray, and scans the laser marked data matrix code via sterile field scanner before handing it off to the surgeon. Staff noted that it’s the first time they have been able to fully document hospital sterilized implants before being handed off to the surgeon and requires no extra staff.

Wheeling Hospital in West Virginia has become the first U.S. hospital to use the sterile field scanner for UDI documentation during surgery.

David B. Cohen, M.D., the neurosurgeon who carried out the first surgery employing the scanner, reported his satisfaction with the new medical device documentation system, saying, “Scanning the UDI was easy and efficient as it did not delay the surgical process.”

Wheeling Hospital chief information officer David Rapp said: “Wheeling Hospital is a technologically advanced hospital. As Chief Information Officer (CIO), I wanted Wheeling to be first to utilize this new technology. My hope was that it would integrate seamlessly in the operating theater.

“Change can be difficult and it’s important that a new technology doesn’t interfere with surgery. I’m delighted to say that in our first clinical use, the feedback I’ve had from the clinical staff was overwhelmingly positive.”

Source: Company Press Release