PrintRoll platform facilitates 3D printing of cylindrical medical solutions for vascular, digestive, respiratory, and reproductive channels on the 3D-Bioplotter system, a complex extrusion-based 3D printer that processes liquids, melts, pastes, gels, and other materials

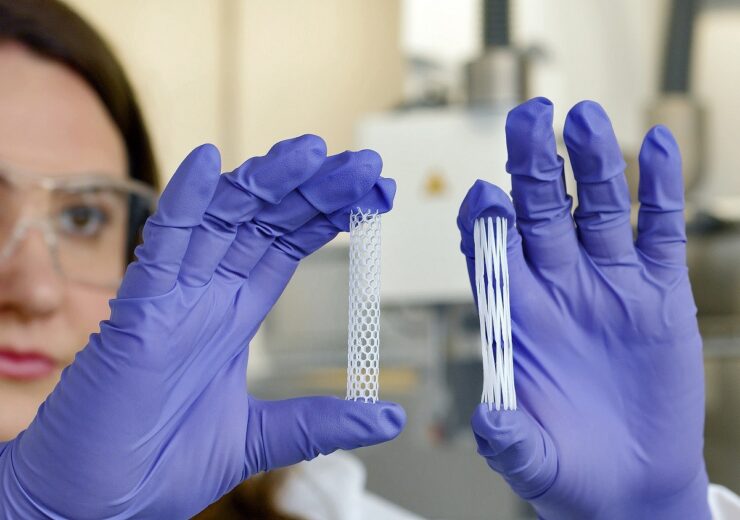

Tubular medical devices printed using PrintRoll rotating build platform. (Credit: Business Wire)

Desktop Health, a medical 3D printing brand of Desktop Metal, has introduced PrintRoll, an advanced rotating build platform that offers medical solutions for adults and children.

PrintRoll platform facilitates the 3D printing of cylindrical medical solutions for vascular, digestive, respiratory, and reproductive channels on the 3D-Bioplotter system.

3D-Bioplotter is a complex extrusion-based 3D printer that processes liquids, melts, pastes, gels, or other materials, including cells, through a needle tip on a three-axis gantry system.

The system offers eight printheads with a wide range of temperatures in bioprinting, from 2°C to 500°C, enabling complex, multi-material medical parts.

PrintRoll was developed as an add-on feature for the 3D-Bioplotter system for bioprinting.

Desktop Health has been developing PrintRoll since 2019 in collaboration with Johannes Gutenberg University Mainz, a public research university in Mainz, Germany.

Desktop Metal founder and CEO Ric Fulop said: “We are proud to offer the first bioprinting tool specifically designed to develop medical solutions for the thousands of miles of channels found in the human body.

“Desktop Health exists to deliver 3D printing solutions that improve patient lives, and we are confident that PrintRoll, offered exclusively on the 3D-Bioplotter, will enable all-new regenerative innovations.”

Attached to the modular build plate of the 3D-Bioplotter, the PrintRoll platform features a motor-driven rotating mandrel with spring-loaded, easily exchangeable drums of different sizes.

The 3D-Bioplotter’s software sharply controls the rotating speed of the PrintRoll tool, which allows the printhead to move back and forth to deposit material in the desired design.

PrintRoll comes with a 10mm drum diameter, along with 20mm and 40mm sizes, to facilitate the development of solutions for different human channels, based on age and gender.

It also comes with a library of honeycomb designs and standard printing parameters and supports printing hollow cylindrical structures up to 140mm, said the 3D printing company.

Desktop Health biomaterials and innovation VP Nicole Black said: “Up until now, the creation of thin-walled cylindrical devices with complex structured walls has been challenging to accomplish with regenerative materials, such as hydrogels.

“With the PrintRoll, materials are patterned directly on top of a substrate that rolls as the printhead also moves, supporting the deposited layers and therefore expanding the palette of materials that can be 3D printed into these important structures.

“Following printing, devices can be removed from the PrintRoll, leaving high-resolution and reproducible parts that customers have come to expect from the 3D-Bioplotter.”