The Canada-based company has developed these off-the-shelf products using its proprietary and new dry-spinning technology, which is designed to create collagen fibres at commercial scales

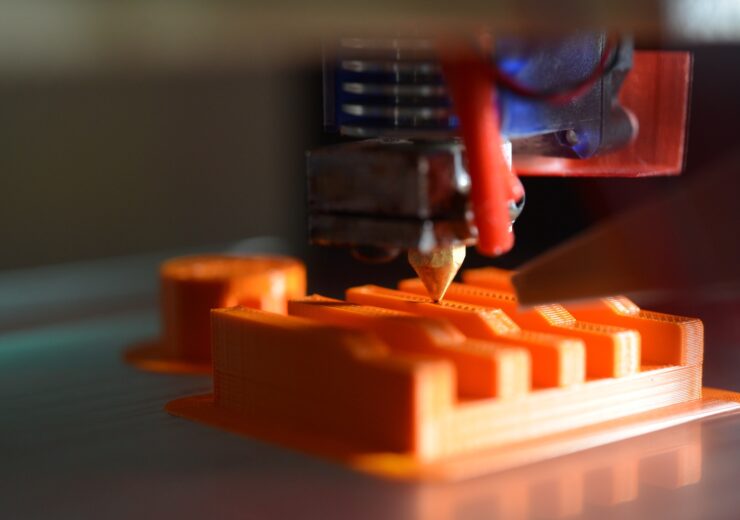

μCollaFibR and CollaFibR 3D scaffold are designed to support tissue engineering and tissue culture applications. (Credit: Gavin Allanwood on Unsplash)

Tissue engineering company 3D BioFibR has announced the launch of two new collagen fibre products dubbed μCollaFibR and CollaFibR 3D scaffold for the bioprinting and 3D cell culture market.

The Canada-based 3D BioFibR has used its proprietary and new dry-spinning technology to make these off-the-shelf tissue engineering products. The technology is intended to create collagen fibres at commercial scales.

Available for the scientific and medical communities, the products offer considerable advantages for tissue engineering and tissue culture applications, said the company.

μCollaFibR is a bioink additive for 3D bioprinting of tissue and organ models in a laboratory setting. It replicates the body’s natural cellular scaffold and functions as a biological rebar in bioinks used for printing live tissues.

The product also enhances the mechanical durability of printed tissues when added to bioinks, enabling the layer-by-layer assembly of various cell types to create highly functioning tissue and organ models, the tissue engineering firm said.

3D BioFibR CEO Kevin Sullivan said: “3D bioprinting is the future of regenerative medicine and it’s exciting to offer μCollaFibR to enhance the capabilities in 3D bioprinting.

“We all want to imagine a future where doctors could just print a kidney, using cells from the patient, instead of having to find a donor match. Our collagen fibres represent a significant improvement over existing scaffolds used in 3D bioprinting, moving the field closer to this reality.”

The CollaFibR scaffold for 3D cell culture is designed to enable researchers to analyse cellular reactions in a more physiologically appropriate 3D environment, compared to conventional 2D cultures.

It uses GMP type 1 collagen to create a collagen fibre matrix that is consistent and mimics the biomechanical and biochemical characteristics of natural cellular environments.

Sullivan said: “Our CollaFibR scaffold allows cells to grow and interact with the surrounding cellular scaffold in 3D, making it ideal for creating realistic tissue constructs for laboratory testing of new drugs and tissue models.

“Plus, our standard well plate dimensions are compatible with automated equipment for high throughput compound screening and advanced microscopy.”