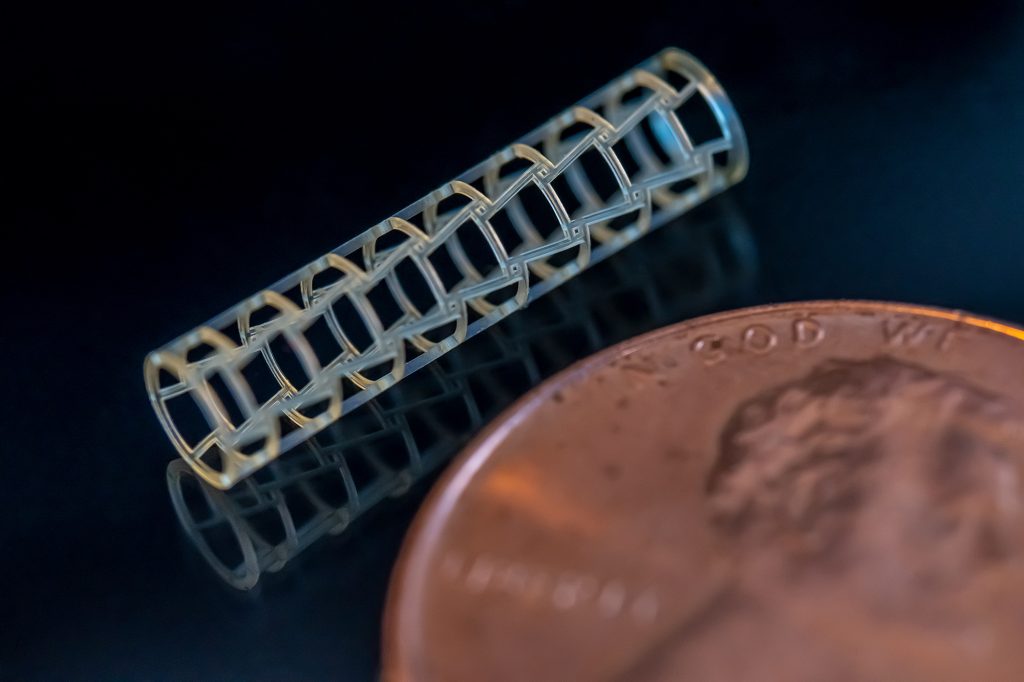

Many of the world’s products are getting smaller and smaller. One major limitation in the trend towards smaller products is the inability to use traditional manufacturing methods to cost effectively prototype and produce the small parts. Until now, there haven’t been any good 3D printing alternatives to producing these small parts due to a lack of technology with the ability to get the resolution and accuracy needed in parts of this size.

Boston Micro Fabrication (BMF) is the leading manufacturer of industrial micro-precision 3D printers. Founded in 2016, BMF has offices in Singapore, Boston, Shenzhen and Tokyo. We use an innovative technology called Projection Micro Stereolithography (PµSL), a technique that allows for rapid photopolymerization of a layer of liquid polymer using a flash of UV light at micro-scale resolution.

Using industrial-grade composite polymers and ceramics, BMF is capable of achieving resolution of 2µm-50µm and tolerance of +/-5µm-25µm, thus providing mold-free, ultra-high-resolution fast prototyping and end part capability. At the forefront of micro 3D precision manufacturing, BMF is the only industrial 3D printing company to match the quality of high-resolution injection molding and CNC processing.

The microArchTM series is the first commercialized high-resolution, 3D microfabrication equipment based on PµSL technology. The superior production of intricate, exact, and replicable parts makes PµSL the optimal prototypic process for various use cases across a wide variety of industries.

Micro 3D printing is the optimal manufacturing process for a variety of 3D printing applications across a wide variety of industries. The combination of ultra-high resolution, accuracy, and precision allows for more intricate, exact, and replicable parts. BMF’s open material system allows you to print with our specifically formulated liquid polymers or to print with the material of your choice. Whether you use BMF’s materials or choose your own, you have a variety of options available that will allow you to achieve the results you need based on your application.

For more information on BMF please visit www.bmf3d.com.